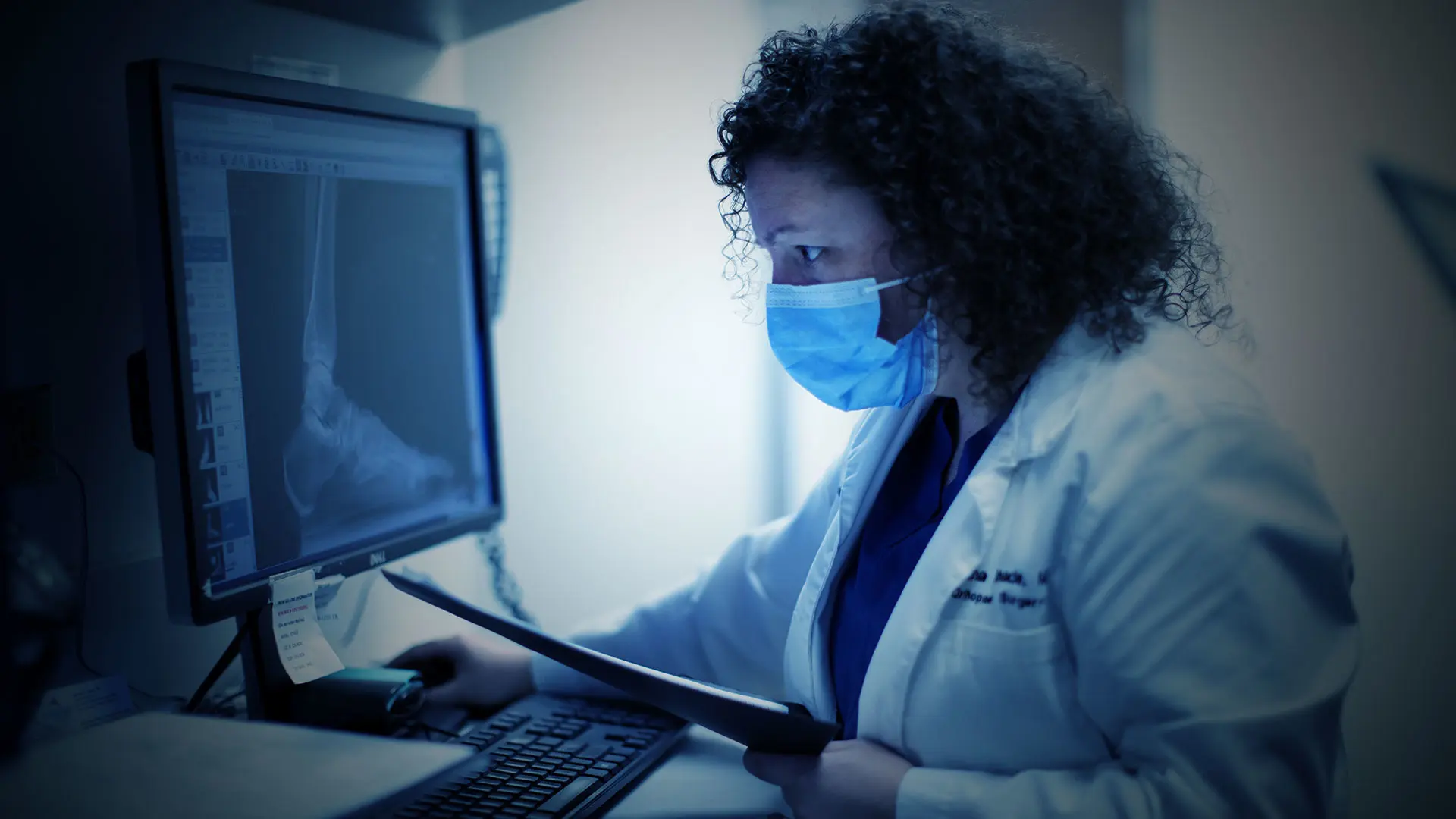

Ankle and foot reconstruction can be among the most complex cases for orthopedic surgeons given the degree of bone loss and deformity that advanced ankle osteoarthritis, injury and trauma, or infection can cause. Increasingly, 3D printing technology is providing a novel and highly effective solution. This emerging technology is allowing physicians such as Meghan Kelly, MD, PhD, Assistant Professor of Orthopedics at the Icahn School of Medicine at Mount Sinai, to perform total ankle arthroplasty with durable implants that precisely fit the patient’s anatomy and allow for accurate hardware placement while delivering superior long-term results.

“Our emphasis is on minimizing bone resection, because the more talus we leave in place, the more likely natural bone will allow for bone ingrowth into the implant,” says Dr. Kelly, who specializes in foot and ankle disorders. “That’s where 3D printing is really helpful, because it provides a detailed anatomical model that enables us to preplan the surgery and also to develop custom metal implants that not only conform to the patient’s exact anatomy but promote bone growth. Essentially, 3D printing presents a great road map that enhances the performance and confidence of the surgeon performing total ankle replacement, Charcot foot surgery, and other orthopedic procedures.”

Advancing Total Ankle Arthroplasty Using 3D Printing Technology

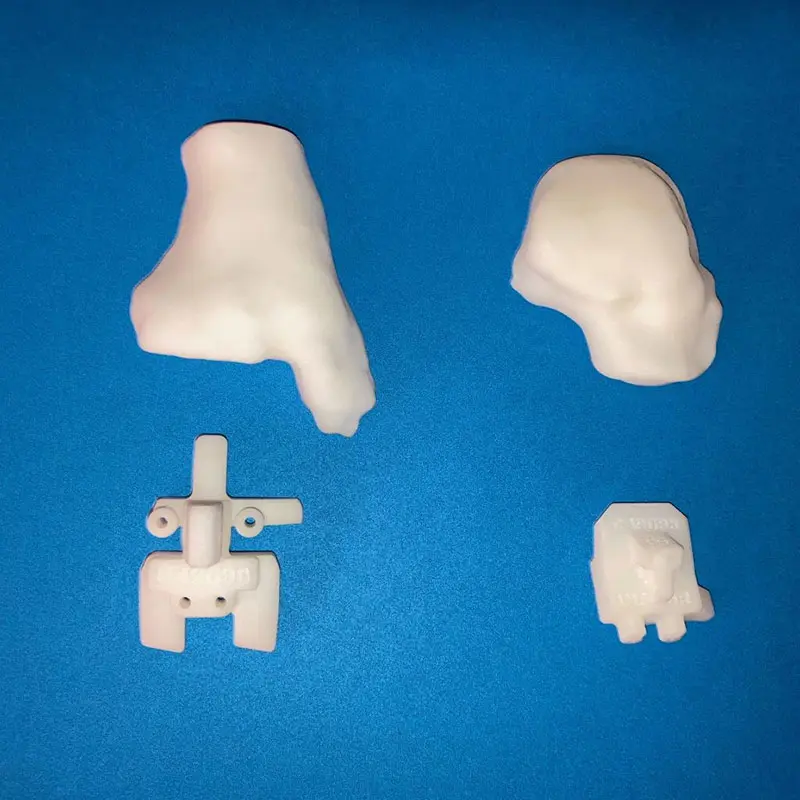

The technology is particularly helpful when weighed against traditional structural bone grafts, which are difficult to contour to the patient’s anatomy and often degrade over time, compromising their mechanical integrity. In total ankle arthroplasty, the ankle joint is removed and replaced by an implant made of metal (often cobalt-chrome) and polyethylene. Using Dr. Kelly’s approach, the procedure begins with preoperative computed tomography (CT) imaging of the patient’s lower extremity, which she sends to a company specializing in 3D printing. That provider creates 3D-printed jigs and a detailed report for Dr. Kelly, which provides a preoperative plan and estimated sizing of the implant components. The report serves as both a precise planning model to precontour the implant to ensure it anatomically fits the patient, and to guide positioning of the jigs once surgery begins to hold the new joint in place. In certain settings, the prosthesis can be further customized to account for inherent bone loss, which would otherwise make an ankle replacement contraindicated.

3D-printed tibia and talus based on preoperative CT scan (top) and 3D-printed jigs for tibia and talar cutting guides for total ankle arthroplasty (bottom).

3D-printed jigs for placement of tibial and talar cutting guides for a total ankle arthroplasty positioned on 3D-printed tibia and talus pieces based on preoperative CT scan.

For Dr. Kelly, successful total ankle replacement means finding the right surgical candidate. “Where the procedure really shines is in patients who have more unusual anatomies, so that we can streamline the implant to the patient,” she explains. “In these cases, ankle replacement surgery using 3D-printed jigs can significantly relieve pain and restore a functional range of motion to a joint—the kind of flexibility that isn’t possible with ankle fusion surgery.” In a growing number of cases, Dr. Kelly points out, total talus replacement is being combined with total ankle replacement to further preserve range of motion when the talus is severely compromised.

Using 3D Printing Technology for Charcot Arthropathy Reconstruction

Dr. Kelly joins a growing number of orthopedic surgeons who can use 3D printing technology for reconstructions in the setting of Charcot arthropathy. These infections often leave large gaps between healthy and diseased bone, a condition that a somewhat different 3D printing application may be well equipped to address. It involves creating a trabecular-coated metal cage that is filled with bone graft, which is inserted in those areas in a patient’s foot where CT scans or X-rays have shown that bone is lacking. These preprinted components can account for the bone deficits and be designed to allow for placement of additional implants, the ends of which are often coated with a surface that allows for bony ingrowth in a manner similar to that seen with joint replacements.

The excellent presurgical guideposts that 3D printing affords will likely increase its appeal to surgeons who don’t use it regularly for cases of severe ankle deformity, Dr. Kelly firmly believes. “Foot and ankle surgeons who would have previously referred some of these cases to a high-volume academic center may now have more confidence performing a total ankle arthroplasty on their own knowing that 3D printing gives them a valuable helping hand,” she says, adding it can also increase access for patients, since not everyone lives near a large academic center. “Studies suggest that this emerging technology is surgically sound, and, based on the outcomes I’ve seen with my own patients, I plan to not only continue, but expand, its use in the appropriate cases.”

Featured

Meghan Kelly, MD, PhD

Assistant Professor of Orthopedics (Orthopedic Surgery)